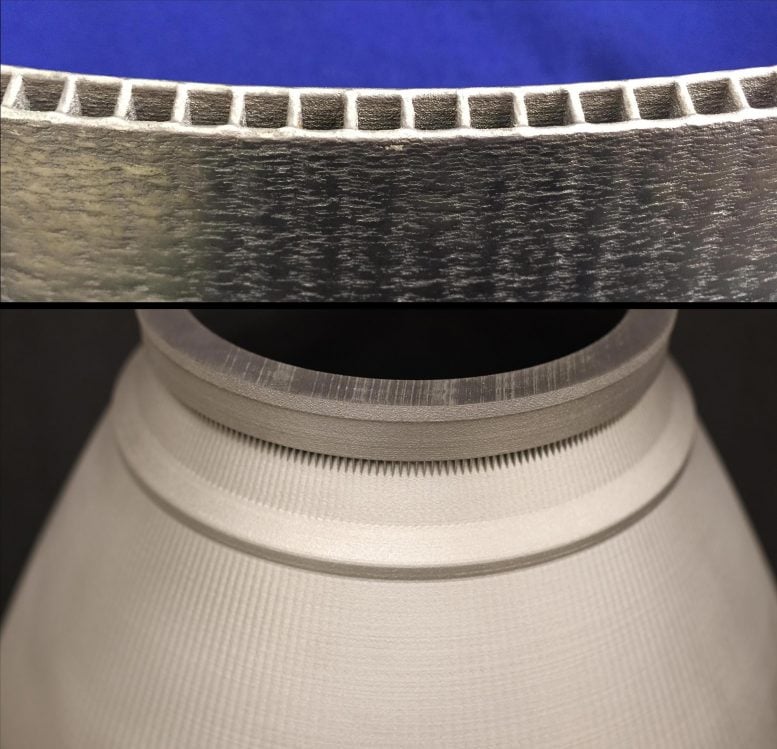

With the help of powder-controlled energy deposition, large structures – such as these motorized nozzles – can be created that are cheaper and faster than conventional manufacturing techniques. Photo credit: NASA

As part of the Artemis program NASA astronauts return to the moon where we will prepare for human exploration Mars. NASA, industry, and science experts in additive manufacturing or 3D printing are pioneering methods of printing the rocket parts that could power those journeys.

NASA’s Rapid Analysis and Manufacturing Propulsion Technology (RAMPT) project is advancing the development of additive manufacturing technology for 3D printing rocket engine parts with metal powder and lasers. The process, known as directed blown powder energy deposition, could reduce costs and lead times for making large, complex engine components such as nozzles and combustion chambers. Previous developments in additive manufacturing did not have the large-scale capabilities that this emerging technology offers.

“This technological advance is significant as it enables us to manufacture the most difficult and expensive rocket engine parts at a lower cost than in the past,” said Drew Hope, manager of NASA’s Game Changing Development Program, which funds the RAMPT project. “In addition, companies inside and outside the aerospace industry can do the same and apply this manufacturing technology to the medical, transportation and infrastructure industries.”

NASA engineers are exploring a new way to 3D print rocket engine parts using metal powder and lasers. The process known as blow powder-directed energy deposition is faster and more cost-effective than conventional manufacturing processes. The development is part of NASA’s Rapid Analysis and Manufacturing Propulsion Technology (RAMPT) project. Photo credit: NASA

The printing process injects metal powder into a laser heated pool of molten metal or a melt pool. The blown powder nozzle and the laser optics are integrated in a print head. This printhead is attached to a robot and moves in a pattern determined by a computer that builds up layer by layer. The manufacturing process has many advantages, including the ability to make very large pieces – limited only by the size of the room in which they are made. It can also be used to print very complex parts, including engine nozzles with internal coolant channels. Rocket engine nozzles, which contain internal coolant channels, allow cryogenic propellant to flow through the channels to keep the nozzle at safe temperatures.

“It is a challenging process to make the nozzles traditionally, and it can take a long time,” said Paul Gradl, RAMPT co-principal investigator at NASA’s Marshall Space Flight Center in Huntsville, Alabama. “With additive manufacturing using powder-controlled powder-controlled energy deposition, we can manufacture very large components with complex internal features that were previously not possible. We can significantly reduce the time and cost of manufacturing channel-cooled nozzles and other critical rocket parts. ”

Complex constructions – such as B. Motor nozzles with integrated channel walls – can be produced by blowing off powder-controlled energy separation. The sides of the nozzle and channel walls at the top are only as thick as some pieces of notebook paper. Photo credit: NASA

The RAMPT team recently used the technique to make one of the largest nozzles NASA has printed. It is 40 “in diameter and 38” high with fully integrated cooling channels. This nozzle was manufactured in record time – just 30 days compared to almost a year using traditional welding methods – and was completed a year ahead of schedule as the technology was advancing rapidly.

The success of the RAMPT project caught the attention of NASA’s Space Launch System SLSMissile team. NASA’s SLS, along with the Orion spacecraft, forms the backbone of our space exploration plans, including sending the first woman and next man to the moon in 2024 and establishing sustainable exploration by the end of the decade. The SLS program is investing in RAMPT’s manufacturing process for powder-based powder-controlled energy deposition with the aim of certifying it for space travel. Working with RAMPT, the team uses this technique to build and evaluate a channel-cooled nozzle up to 5 feet in diameter and nearly 7 feet high.

“Making duct wall nozzles and other components using this new type of additive manufacturing would allow us to manufacture the SLS motors on the scale required with a reduced schedule and cost,” said Johnny Heflin, liquid motor office manager for the SLS- Program.

Through a series of rigorous hot burn tests, engineers will expose a sub-scale version of the nozzle to the same combustion temperatures and sustained 6,000 degrees pressures it would be exposed to during launch to demonstrate the durability and performance of the new directional energy deposition technology.

Public private partnership

While NASA leads the technology development expedition, partnerships with science and industry play an important role. Through an agreement with Auburn University in Alabama, RAMPT works with specialty manufacturers who are already advancing the “state of the art” to improve their work and make the technologies developed by this team fully available to the private sector. These public-private partnerships also add value to NASA missions as the partners share some development costs.

NASA’s investments in direct energy deposition manufacturing technology for blow powder and materials development will play a critical role in enabling the agency’s most ambitious exploration missions. Technology can play a vital role in many other industries as well, including commercial real estate, and help make the world a better place for every print.

The RAMPT project is funded by NASA’s Game Changing Development program within the Directorate for Space Technology Mission. RAMPT includes partners from across the agency, including NASA’s Glenn Research Center in Cleveland, NASA’s Ames Research Center in Silicon Valley, California, industry and science.