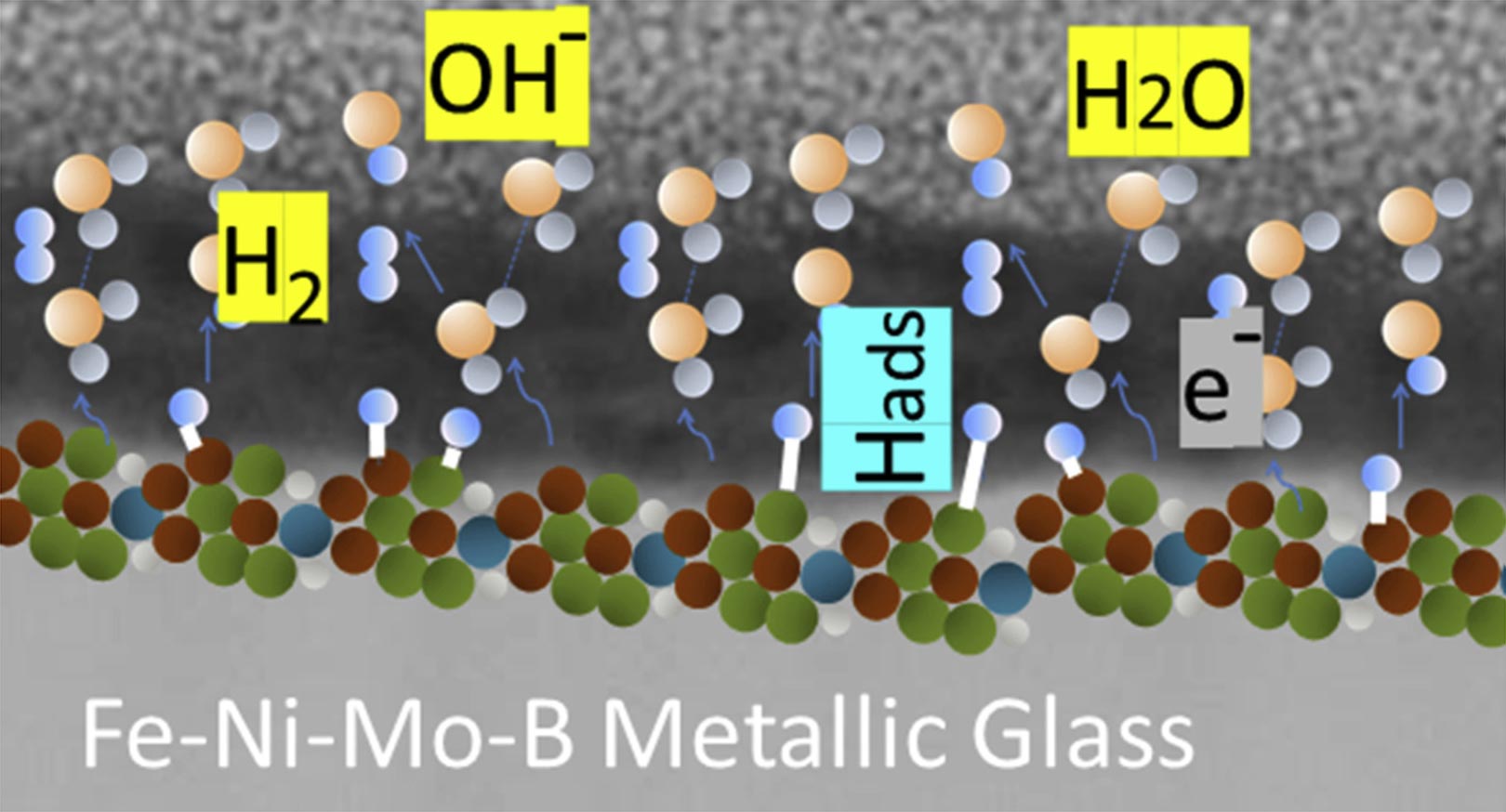

Fe-Ni-Mo-B Metallic Glass, graphically all abstract. Photo credit: FEFU press office

A team of scientists from Far Eastern Federal University (FEFU), together with their colleagues from Austria, Turkey, Slovakia, Russia (MISIS, MSU) and Great Britain, found a way to hydrogenate thin metallic glass layers at room temperature. This technology can greatly expand the range of cheap, energy-efficient and high-performance materials and methods that can be used in the field of hydrogen energy. An article about the study was published in the Journal of Power Sources.

The team developed an amorphous nanostructure (metal glass based on FeNi) that can be used in the field of hydrogen energy to accumulate and store hydrogen, especially as a replacement for Li-ion batteries in small systems.

Metallic glass can replace palladium, an expensive element currently used in hydrogen systems. The lack of economically viable energy storage systems is the main obstacle to preventing hydrogen from increasing to industrial levels. With the new development, the team came one step closer to solving this problem.

“Hydrogen is the most abundant chemical element in the universe, a source of clean renewable energy that has the potential to replace all of the fuels used today. However, storage is a major technological problem. Palladium is one of the key materials used to store and catalyze hydrogen. However, it is very expensive and has a low affinity for oxidizing or reducing environments under extreme conditions. These factors prevent hydrogen from being used on an industrial scale. The problem can be solved with metallic glasses. They are amorphous metals and do not have a long range atomic order. Compared to crystalline palladium, metallic glasses are much cheaper and more resistant to aggressive environments. In addition, because of what is known as the atomic free volume (ie the space between atoms), such glasses can “hold” hydrogen more effectively than any other material with a crystalline structure, ”said Yurii Ivanov, assistant professor in the Department of Computer Systems at the Faculty of Science, FEFU.

According to the researcher, metallic glass has enormous potential in the energy industry due to its amorphous structure, the lack of certain defects typical of polycrystalline metals (such as grain boundaries) and its high resistance to oxidation and corrosion.

What makes this work unique is the fact that electrochemical methods have been used both to hydrogenate metal glasses and to study their ability to absorb hydrogen. Standard hydrogenation methods (such as gas adsorption) require high temperature and pressure, which negatively affects the properties of metal glasses and limits the range of materials that can be used in the study. In contrast to gas adsorption, electrochemical hydrogenation causes hydrogen to react with the surface of an electrode (made of FeNi metal glass) at room temperature, just as in the case of palladium.

The new process can be used as an alternative to the traditional gas-solid reaction for alloys with low capacity or hydrogen absorption / release rate.

The team also proposed a new concept of “effective volume” that can be used to analyze the efficiency of hydrogen absorption and release by metallic glasses. For this purpose, the thickness and composition of the glass-hydrogen reaction area are measured using high-resolution electron microscopy and X-ray photoelectron spectroscopy.

In the future, the team plans to develop and optimize new metallic glass compositions for practical energy applications.

Previously, a team of materials scientists from FEFU, Cambridge (UK) and the Chinese Academy of Sciences had developed a method for “rejuvenating” 3D metal glasses which are most promising for practical use. The glasses were more malleable and more resistant to supercritical loads. The improved metal glasses can be used in many areas, from plastic electronics to various sensors and transformer cores, medical implants and protective coatings on satellites.

Reference: “Perspective on surface-controlled electrochemical hydrogenation in metallic glass based on FeNi” by Baran Sarac, Vladislav Zadorozhnyy, Yurii P. Ivanov, Askar Kvaratskheliy, Sergey Ketov, Tolga Karazehir. Selin Gumru, Elena Berdonosova, Michail Zadorozhnyy, Matej Micusik, Maria Omastova, A. Sezai Sarac, A. Lindsay Greer and Jürgen Eckert, August 15, 2020, Journal of Power Sources.

DOI: 10.1016 / j.jpowsour.2020.228700