This video clip shows a 3D printing technique in which a printer head scans every layer of a part and blows metal powder that is melted by a laser. It is one of several ways parts are 3D printed NASAHowever, the Jet Propulsion Laboratory was not used to manufacture the parts on board the Perseverance Rover.

For hobbyists and doers, 3D printing expands the creative possibilities. For specialized engineers, this is also key to the design of next-generation spacecraft.

If you want to see science fiction at work, head to a modern machine shop where 3D printers make materials in just about any shape imaginable. NASA is researching the technique – known as additive manufacturing when used by specialized engineers – to build rocket engines, as well as potential outposts on the Moon and Mars. Another milestone is closer in the future: NASA’s Perseverance Rover, which will land on the Red Planet on February 18, 2021, carries 11 metal parts that have been 3D printed.

Instead of forging, shaping, or cutting materials, 3D printing uses lasers to melt powder in successive layers and shape something. This allows engineers to play around with unique designs and features, such as: B. by making hardware lighter, stronger or responsive to heat or cold.

“It’s like doing paper mache,” said Andre Pate, the additive manufacturing group leader at NASA’s Jet Propulsion Laboratory in Southern California. “You build every feature layer by layer and you have a detailed part soon.”

Curiosity, the predecessor of Perseverance, was the first mission to bring 3D printing to the Red Planet. It landed in 2012 with a 3D-printed ceramic part in the rover’s oven-like sample analysis Mars (SAM) instrument. NASA has since continued testing 3D printing for use on spacecraft to ensure the reliability of the parts is well understood.

As “secondary structures”, the printed parts of Perseverance would not jeopardize the mission if they did not work as planned. However, Godfather said, “Flying these parts to Mars is a huge milestone that opens the door to additive manufacturing a little more in the space industry. ”

The outer shell of PIXL, one of the instruments aboard NASA’s Perseverance Mars Rover, consists of several parts made from 3D-printed titanium. The inset shows the front half of the two-part shell piece that was completed. Photo credit: NASA / JPL-Caltech

A shell for PIXL

Of the 11 printed parts going to Mars, five are in Perseverance’s PIXL instrument. The lunchbox-sized device, short for Planetary Instrument for X-Ray Lithochemistry, helps the rover find signs of fossilized microbial life by shooting X-rays at rock surfaces to analyze them.

PIXL shares the space with other tools in the 40-kilogram rotating tower at the end of the rover’s 2-meter-long robotic arm. To make the instrument as light as possible, you have to JPL The team designed PIXL’s two-piece titanium shell, a mounting frame, and two support struts that attach the shell to the end of the arm so that it is hollow and extremely thin. In fact, the parts 3D printed by a manufacturer called Carpenter Additive are three or four times less massive than if they were made conventionally.

“In the truest sense of the word, 3D printing made this instrument possible,” said Michael Schein, PIXL’s lead mechanical engineer at JPL. “With these techniques, we were able to achieve a low mass and high-precision alignment that was not possible with conventional manufacturing.”

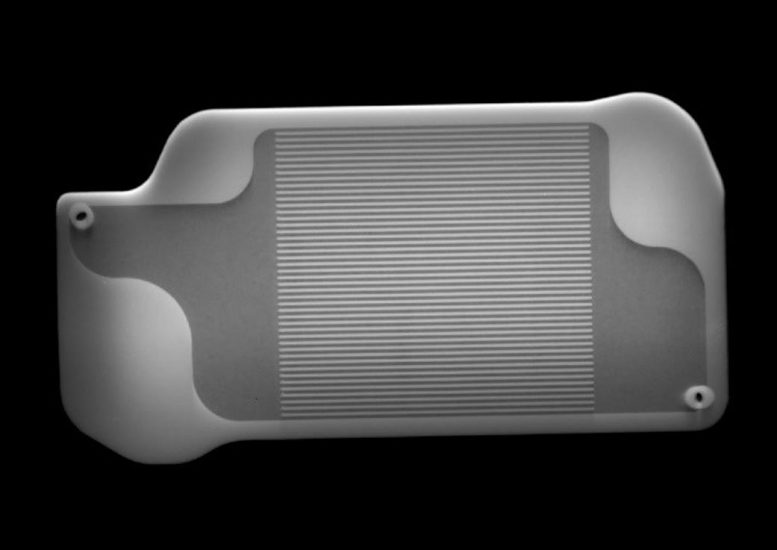

This x-ray shows the inside of a 3D printed heat exchanger in Perseverance’s MOXIE instrument. X-rays like this are used to check parts for defects. Photo credit: NASA / JPL-Caltech

MOXIE turns up the heat

The six other 3D printed parts of Perseverance are in an instrument called the MOXIE (Mars Oxygen In-Situ Resource Utilization Experiment). This device will test technologies that could in the future produce industrial quantities of oxygen to create rocket propellants on Mars and help astronauts return to Earth.

To generate oxygen, MOXIE heats the Martian air to almost 1,500 degrees Fahrenheit (800 degrees Celsius). Inside the device are six heat exchangers – palm-sized nickelalloy Plates that protect important parts of the instrument from the effects of high temperatures.

While a conventionally machined heat exchanger would consist of two parts and would have to be welded together, MOXIES were 3D-printed as individual pieces at Caltech, which JPL manages for NASA.

“This type of nickel part is called a superalloy because it maintains its strength even at very high temperatures,” said Samad Firdosy, materials engineer at JPL who helped develop the heat exchangers. “Superalloys are usually found in jet engines or power generation turbines. They are very good against corrosion, even if they are very hot. ”

Although the new manufacturing process is convenient, any layer of alloy that the printer applies can create pores or cracks that can weaken the material. To avoid this, the plates were treated in a hot isostatic press – a gas breaker – which heats the material to over 1,000 degrees Celsius and exerts evenly strong pressure around the part. The engineers then used microscopes and lots of mechanical tests to check the microstructure of the heat exchangers and make sure they were suitable for space travel.

“I really love microstructures,” said Firdosy. “For me, it’s very cool to see that kind of detail in printing material and how it evolves to make this functional part that flies to Mars.”

More about the mission

A key objective of Perseverance’s mission to Mars is astrobiology, including finding signs of ancient microbial life. The rover will characterize the planet’s geology and past climate, pave the way for human exploration of the red planet, and be the first mission to collect and cache Martian rocks and regolith (broken rock and dust).

Subsequent missions, currently under review by NASA in collaboration with ESA (European Space Agency), would send spacecraft to Mars to collect these cached samples from the surface and bring them back to Earth for in-depth analysis.

The Mars 2020 mission is part of a larger program that includes missions to the moon in preparation for human exploration of the red planet. NASA is slated to bring astronauts back to the moon by 2024 and establish a sustained human presence on and around the moon by 2028 through NASA’s Artemis lunar exploration plans.

JPL, managed for NASA by Caltech in Pasadena, Southern California, built and manages the operations of the Perseverance and Curiosity rovers.