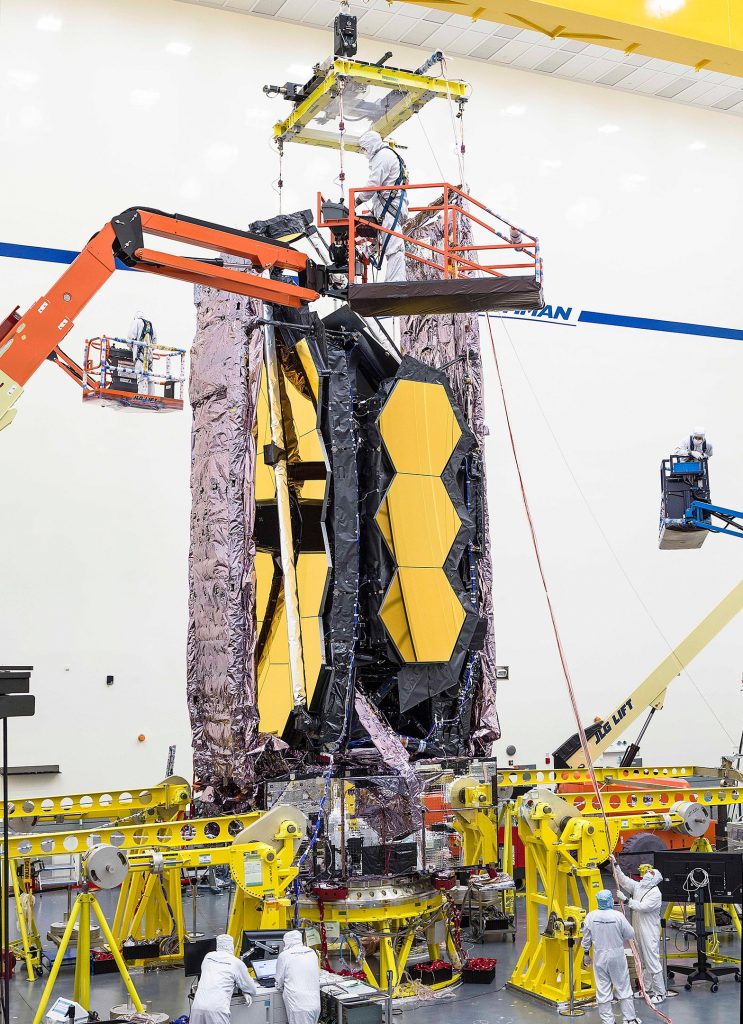

For the first time, test teams from Northrop Grumman in Redondo Beach, Calif., Carefully lifted the assembled James Webb space telescope to prepare it for transport to nearby acoustic and sinusoidal vibration test facilities. Photo credit: NASA / Chris Gunn

With the completion of the latest series of milestone tests NASA‘s James Webb Space Telescope has now survived all of the harsh conditions associated with a rocket launch into space.

Webb’s recent tests have confirmed that the fully assembled observatory can withstand the deafening noise and jolts, rattles and vibrations the observatory experiences when it takes off. NASA, known as “acoustic” and “sinusoidal vibration” tests, has worked carefully with its international partners to fine-tune Webb’s testing environment for what Webb will experience both on launch day and in orbit.

For the first time, test teams from Northrop Grumman in Redondo Beach, Calif., Carefully lifted the assembled James Webb space telescope to prepare it for transport to nearby acoustic and sinusoidal vibration test facilities. Photo credit: NASA / Chris Gunn

Although every component of the telescope was rigorously tested during development, demonstrating that the assembled flight hardware can safely pass through a simulated launch environment is a significant achievement for the mission. Conducted at two separate facilities at Northrop Grumman’s Space Park in Redondo Beach, Calif., These tests represent the last two Webb in a long line of environmental tests before Webb is shipped to French Guiana for launch.

The closest environment Webb will experience is space.

“The successful completion of our environmental tests in the observatory is a monumental milestone on the way to the start. Environmental tests show that Webb can survive the rocket trip into space. This is the most violent part of his journey into orbit, which is roughly a million miles from Earth. The multinational group of people responsible for conducting the acoustic and vibration test is made up of an outstanding and dedicated group of people typical of the entire Webb team, ”said Bill Ochs, Webb project manager for the NASA’s Goddard Space Flight Center in Greenbelt, Maryland.

The tests began with the entire telescope first being encapsulated in a mobile clean room that was supposed to protect it from the outside world. Technicians then carefully guided it to a nearby acoustic test chamber, where it was deliberately blasted with sound pressure levels above 140 decibels. The spectrum was tailored to the specific signature of the Ariane 5 rocket it will use to fly into space. Nearly 600 individual movement channels were carefully observed and recorded during the tests. Typical acoustic and vibration tests measure approximately 100 channels of data, but the complex size and shape of the observatory required significantly more measurements to ensure success. The data was then thoroughly analyzed and marked as a complete success.

To move the James Webb Space Telescope safely between test facilities, engineers lock it in a special mobile clean room, often called a clamshell. Creeping between buildings can take hours and requires lifting phone lines so Webb can go under. Webb’s recent tests have confirmed that the fully assembled observatory can withstand the deafening noise and jolts, rattles and vibrations the observatory can withstand when it takes off. NASA, known as “acoustic” and “sinusoidal vibration” tests, has worked carefully with its international partners to fine-tune Webb’s testing environment for what Webb will experience both on launch day and in orbit. Photo credit: NASA’s Goddard Space Flight Center

After successfully completing the final acoustic tests, Webb was repackaged and transported to a separate facility to simulate the low-frequency vibrations that occur when it takes off. Inside, Webb was placed on a special shaking table that enables precise vertical and horizontal acceleration. While acoustic tests simulate the high-frequency dynamics of take-off, vibration tests cover the lower frequencies. Combining the two takes into account all of the mechanical environment Webb will experience during startup.

“The test team is an international consortium of structural dynamics experts who are the lead engineers for each hardware on the observatory. The team members are represented in 9 time zones in the USA and Europe! They go out of their way to provide 24/7 testing to provide their expertise, ”said Sandra Irish, director of Webb Mechanical Systems Structures Engineer for NASA’s Goddard Space Flight Center in Greenbelt, Maryland. “With the dedication of the team, the hard work and the sheer excitement of being part of this complex test, it was a complete success! I have known these people for many years and it has been an honor to work with each of them. ”

Webb is now set to proceed with the final full expansion of its iconic primary mirror and sunshade, followed by a full system assessment before being encapsulated in a special shipping container for shipping to South America. Deploying the observatory after experiencing a simulated launch environment is the best way to replicate the true series of events the observatory will experience during launch and while performing its complex deployment sequence in space. The initial analysis suggests that the observatory successfully passed the acoustic and vibration tests at the observatory level. However, the full flightworthiness check will be carried out after Webb has successfully completed the final field tests.

Engineers and technicians obey due to the COVID-19 Situation causing significant impact and disruption worldwide. The team has resumed almost complete operation and is now preparing for the final test phase before shipping to the starting location.

The James Webb Space Telescope is the world’s largest, most powerful, and most complex space telescope ever built. In addition to the groundbreaking science expected upon its launch, Webb has required improvements to the testing infrastructure and processes involved in validating large complex spacecraft for life in space. Various facilities across the country needed to be expanded and upgraded to safely test a machine the size of Webb and prepare it for launch. Lessons from the earlier development of space telescopes have been invested in Webb, and future space telescopes will build on the same collective knowledge. Thousands of scientists, engineers, and technicians have helped build, test, and integrate Webb. A total of 258 companies, agencies and universities took part – 142 from the USA, 104 from 12 European countries and 12 from Canada.

Webb is NASA’s next major space exploration observatory that will help solve the mysteries of our solar system, look beyond distant worlds to other stars, and explore the mystifying structures and origins of our universe. Webb is an international program led by NASA together with its partners ESA (European Space Agency) and the Canadian Space Agency.