Protection business firm established in 1975 to fulfill the navy communication wants of the Turkish Armed Forces. ASELSANcontinues to work on this context.

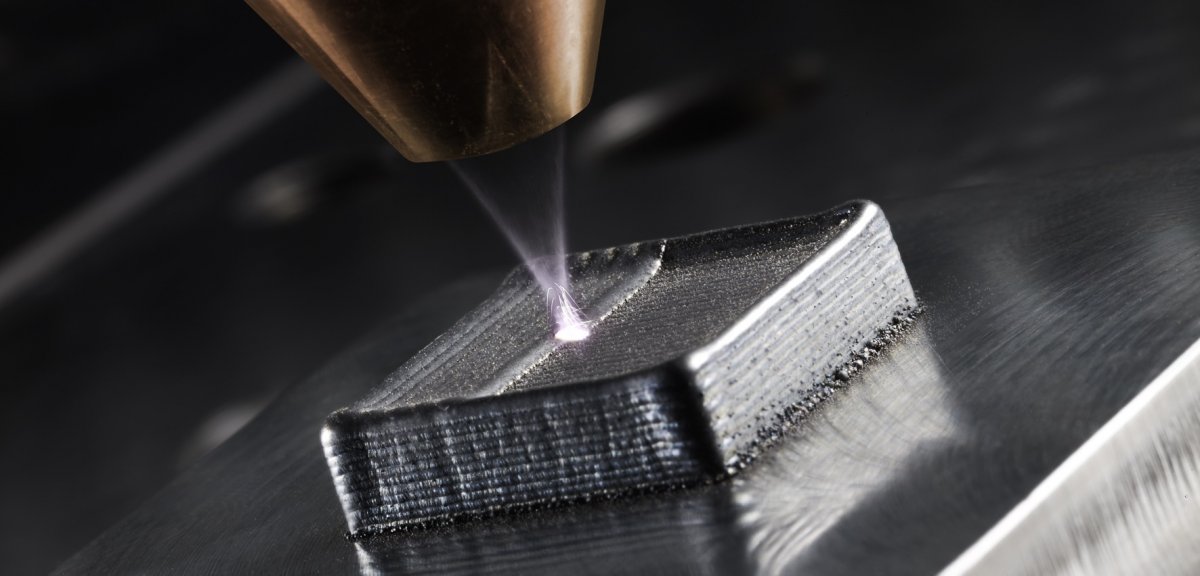

The first firing exams have been carried out efficiently in the Electron Gun Growth Challenge being carried out at ASELSAN.

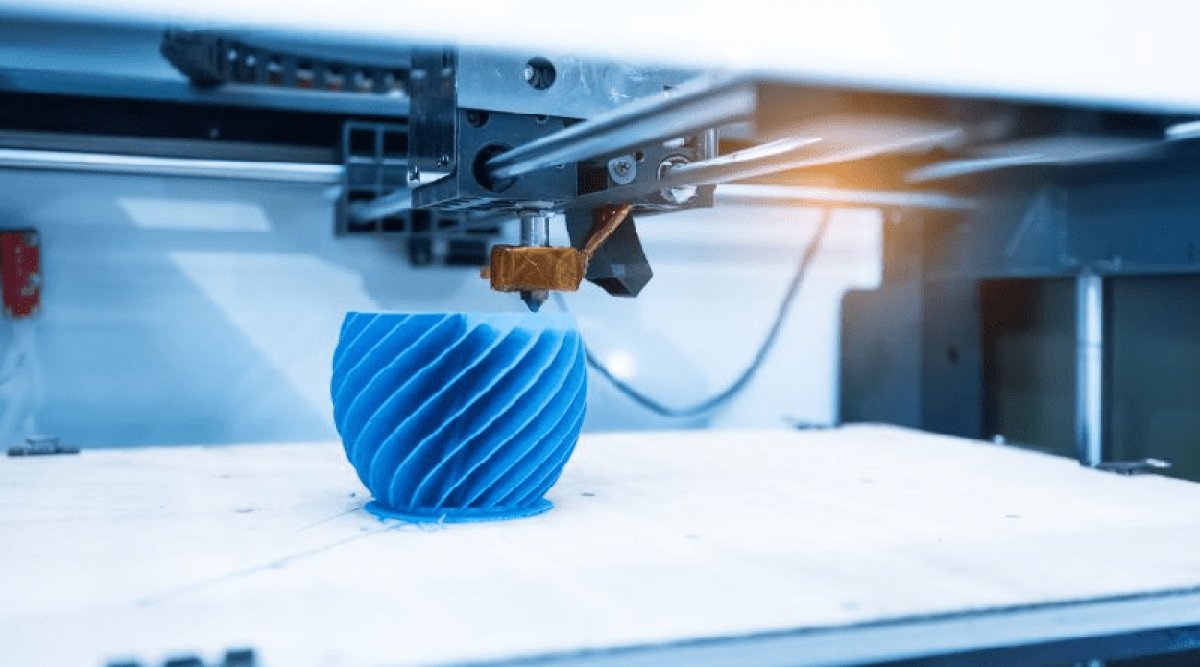

CRITICAL STEP IN DOMESTIC AND NATIONAL 3D PRINTER

The success achieved with the electron gun, which is the most crucial part of 3D printers for additive manufacturing, has enabled one other necessary stage to be handed in the improvement of home and nationwide 3D printers that can be utilized in the subject of protection and aerospace.

In the exams, an electron beam with an influence of 4.32 kilowatts was struck in opposition to a 2-centimeter thick copper take a look at plate beneath vacuum.

The electron beam, which was saved open for 10 seconds, fashioned a soften pool of roughly 1.5 millimeters in diameter on the copper sheet.

To take away the electron beam at increased voltages, a corona ring was designed and fabricated to forestall arcing. Bundle elimination take a look at was carried out with the corona ring.

The designed half offered a profitable end in stopping arc formation, enabling it to achieve the focused 90 kilovolt voltage values.

An electron beam with a voltage of 90 kilovolts and a present of 10 milliamperes was struck in opposition to a 1.2 millimeter thick aluminum plate, making a 1-centimeter-wide gap in the plate.

THIS YEAR WILL BE READY FOR NEW EXPERIMENTS

The electron gun prototype, which is being intensively studied, is the subsequent part this 12 months. “electron beam and metallic powder interplay experiments” will probably be made prepared to be used.

3D PRINTER AND ADDITIVE MANUFACTURING BENEFIT

layered manufacturing is outlined as the superior and industrially functionalized model of the fast prototyping part with 3D printers which have been used for a very long time.

With the assist of additive manufacturing applied sciences, engineers can notice their designs in a short while and produce lighter and extra advanced elements, with the elimination of manufacturing-related constraints.

In the home improvement tasks of plane, helicopters, missiles, unmanned aerial automobiles, satellites, jet engines, that are specified inside the scope of the goal of “Gaining Competence in Protection and Safety Applied sciences” in the Strategic Plan of the Presidency of Protection Industries, efficiency, value, by utilizing additive manufacturing applied sciences, particularly in crucial and expensive metallic elements. and aggressive benefit.

As well as, additive manufacturing applied sciences can be utilized in aviation upkeep actions.

In restore processes, which is the weak level of upkeep organizations, the essential restore supplies may be simply designed and used on the plane due to the additive manufacturing technique.

Thus, whereas quicker options are produced for repairs, massive quantities of restore supplies is not going to be saved in the stock of the institution, and storage prices will lower considerably.

#ASELSAN #ignition #electron #gun

Dikkat: Sitemiz herkese açık bir platform olduğundan, çox fazla kişi paylaşım yapmaktadır. Sitenizden izinsiz paylaşım yapılması durumunda iletişim bölümünden bildirmeniz yeterlidir.

https://m.ensonhaber.com/teknoloji/aselsan-elektron-tabancasiyla-ilk-ateslemeyi-yapti